For now, we only implemented a simple loop to stabilize the power of the outer DAS ring of the NI (TCS_NI_CO2_PWROUT), which is currently still blocked by a shutter. We will leave it running for the weekend to as a test. The time constant of the loop was set to about 100 seconds, see attached figure.

In the next weeks, we will add similar loops for the other TCS beams. Also still to be done is adding protection against the loop spinning out of control (when you go 'over the top of the fringe) and avoiding useless changes of just a few steps due to the noise of the sensor.

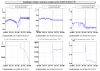

Checked the behavior of the loop over the weekend (See figure): everything seems ok.

XX_MEAN: 10 second running average of the power on the relevant photodiode

XX_SET: set-point in Watt

XX_ON: on/off switch of the loop, set to 0 or 1

XX_GAIN: servo gain in step/(Watt*second)

where XX is TCS_{NI/WI}_CO2_{CH/IN/OUT}. Buttons have been added to VPM to switch the loops on/off and change offset and gain.

On the DAQ side, I had to add the key FDOUT_CONVERT_SERDATA to the config file, since dataDisplay didn't like the fact that two different processes had the same SMS prefix "TCS".

To tune the gain: change the rotator by a decent amount (say 1000 steps) and measure the change in output power to obtain the slope in Watt/step. The gain must then be set to gain = - 1 / (slope * tau), with tau the time constant of the loop (100 second seems to work fine).

Since TCS people were working on the WI bench, I only tuned the gain of the 3 NI loops so far. They have been on since this afternoon and seem to run fine, see attached figure. I will do the WI loops in the next days when possible. I am leaving the 3 loops on for the night, but these should be monitored in the next days, since the algorithm doesn't implement a lot of safety checks yet.

Around 18:45 UTC, however, the central heating beam somehow lost so much power that the rotator could no longer compensate, so the loop went crazy and took the waveplate for a few spins, see fig 2. When I discovered the issue, I stopped the loop and put the rotator close to the top of the fringe, to keep the thermal situation closest to how it was. Note that the loop was stabilized at 12.69 Watt (close to where I found it) and during the calibrations went close to 13 W without effort, but the maximum during the full rotations was only 12 Watt, so it seems that at least a Watt was somehow lost. Note that at the same time the issue with the CH started, the rotator of the DAS outer ring also started moving, but in this case the actuator appeared to have enough range to compensate.

I switched off all loops for the night, but we clearly need to think about some safety that switches the loop off in case things go crazy.

I am leaving all 3 loops of the NI switched on for the weekend at the same power I found them at.